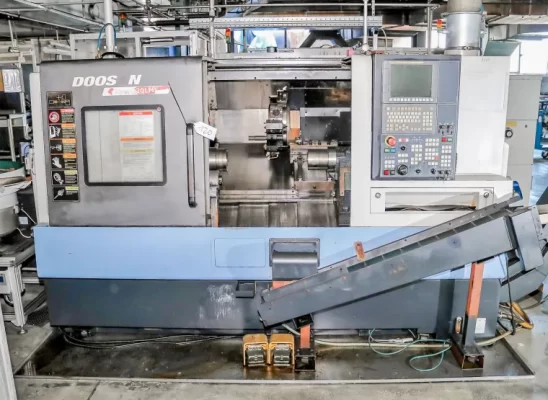

CHEVALIER QP2033-L

The CHEVALIER QP2033-L is a high-quality CNC vertical machining center that offers exceptional performance and versatility. Designed for precision machining, it features a robust construction and advanced features to deliver reliable and accurate results. With its powerful spindle and rapid traverse rates, the QP2033-L enables efficient and high-speed machining operations. The CNC control system ensures ease of operation and allows for seamless programming and control. Equipped with a spacious worktable and flexible tooling options, it accommodates a wide range of workpieces and machining needs. The CHEVALIER QP2033-L is a reliable and versatile solution for industries requiring precision and productivity in their machining processes.

| ITEM | Description | S.A.E. | Metric |

|---|---|---|---|

| Control | Fanuc 0i-M | – | – |

| Table | Table size | 39.4″ x 20.1″ | 1,000 x 510 mm |

| Max. table load | 1,100 lbs. | 500 kg | |

| Travel | X / Y /Z travel | 33.5″ / 20.9″ / 20.1″ | 850 / 530 / 510 mm |

| Spindle | Spindle nose to table surface | 5.9″~26″ | 150~660 mm |

| Spindle center to column | 23.0″ | 585 mm | |

| Spindle taper | #40 Big Plus | – | |

| Spindle speed | Belt drive: 100~10,000 rpm / Direct drive: 120~12,000 rpm | – | |

| Spindle diameter | 2.8″ | 70 mm | |

| Feed rates | Rapid traverse (X / Y / Z) | 1,417/1,417/944 ipm) | 36/36/24 m/min |

| Cutting feed (X / Y / Z) | 39.3~393 ipm | 1~10 m/min | |

| Automatic tool changer | Tool storage capacity | 24+1 arm type | – |

| Tool shank | BT40 (Opt. CT40 or DIN40) | – | |

| Tool change time (tool-to-tool) | 2 sec. | – | |

| Pull stud | P40T-1 | – | |

| Max. tool diameter with adjacent tool | 3.1″ | Ø80 mm | |

| Max. tool length | 11.8″ | 300 mm | |

| Max. tool weight | 15.4 lbs. | 7 kg | |

| Machine dimensions | Floor space (W x D x H) | 95.7″ x 118.9″ x 116.7″ | 2,430 x 3,020 x 2,963 mm |

| Net weight | 12,700 lbs. | 5,800 kg |