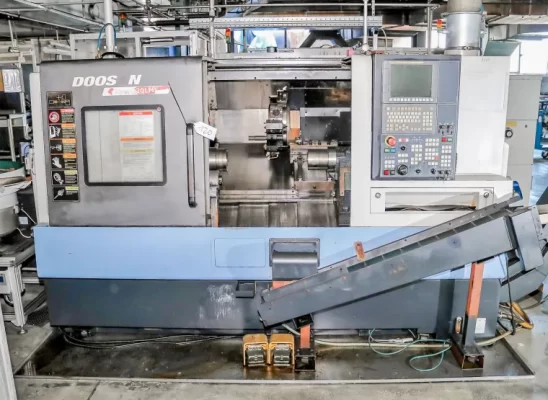

HARDINGE, VMC 800 II, VERTICAL, MACHINING CENTERS

The Hardinge VMC 800 II is a model of vertical machining center designed and manufactured by Hardinge, a well-known company specializing in precision machine tools. The VMC 800 II is specifically engineered for high-precision machining operations in various industries, including aerospace, automotive, and general manufacturing.

POSITIONING TABLE TRAVEL: 15.7″ X 19.6″

WORKTABLE SIZE: 19.6″ X 31.4″

WORK TANK SIZE: 27.5″ X 49.2″ X 18″

PLATEN TO TABLE DISTANCE: 29″ MAX, 5″ MIN

RAM TRAVEL: 12″

BACKSLIDE TRAVEL: 12″

INFEED DISPLAY, 1″ DIAL INDICATOR: .001″/DIV

AUTOMATIC SHUT OFF: ADJUSTABLE

PLATEN SIZE: 7.8″ X 11.8″

MAXIMUM ELECTRODE WEIGHT: 550 LBS

MAXIMUM WORK PIECE WEIGHT: 3,300 LBS

SERVO CONTROLS:

MANUAL, DITHER, EDGE-FINDER, AUTO RETRACT, AUTO LOCK ORBIT STOP, ORBIT LIMIT, SERVO SPEED, GAP ADJUST

H-PULSE 1004 POWER SUPPLIES

EDM CONTROLS:ARC DURATION, % ON-TIME, PEAK CURRENT,POLARITY, ELECTRODE MATERIAL, GAP INITIATION

MAXIMUM AVERAGE CURRENT: 100 AMPS

PEAK CURRENT RANGE PER LEAD: 1 TO 32

NUMBER OF PEAK CURRENT SELECTIONS: 7

GAP INITIATION VOLTAGES: 75, 150, 300 VOLTS

ARC DURATION: 1 TO 3686 MICROSECONDS (60 SELECTIONS)

NUMBER OF LEADS: 2 PER 50 AMP/ POWER SUPPLY 4/100

OVERCUT (INFINITELY VARIABLE): .0005″ / SLIDE

BEST SURFACE FINISH: 10 u INCH RA

MAXIMUM METAL REMOVAL RATE: 4.8 CU IN/HR @ 100A

POSITIVE ELECTRODE (GRAPHITE/STEEL)

SINGLE LEAD OPERATION: 1310 CU mm/MIN

KVA INPUT AT 460 VOLTS: 10.9

DIELECTRIC SYSTEM

WORK TANK CAPACITY: 98 GAL

RESERVOIR CAPACITY: 200 GAL

FLUSHING PRESSURE, ADJUSTABLE: 0 – 50 PSI

VACUUM: 0-15 IN HG

FILTRATION, REPLACEABLE ELEMENT: THREE 5 MICRO ELEMENTS

GENERAL

MACHINE TOOL AND RESERVOIR: 108″ (H) X 98″ (W) X 96″ (D)

POWER SUPPLY: 61″ (H) X 25″ (W) X 30″ (D)

NET WEIGHT: 7,615 LBS

ELECTRICS: 460 VOLTS, 3 PH, 60 CYC

STANDARD EQUIPMENT

1. RUGGED, CAST IRON MACHINE TOOL WITH A PRECISION V-WAY ANTIFRICTION RAM, POWER BACKSLIDE HEAD ADJUSTMENT, V-FLAT TURCITE LINED WORK TABLE WAYS WITH BALL TYPE LEAD SCREW AND NON-INFLUENCING CALIPER WORK TABLE LOCKS

2. BALL TYPE LEAD SCREWS FOR X & Y WORKTABLE POSITIONING

3. TWO DOOR WORK TANK FOR CONVENIENT WORK PIECE SET-UP

4. ULTRA SENSITIVE DC SERVO SYSTEM WITH BALL SCREW DRIVE

5. MICROMETER DEPTH LIMIT STOP WITH AUTOMATIC RAM RETRACT CYCLE

6. DIAL INDICATOR INFEED DISPLAY .001 (.01 MM)

7. DIELECTRIC FLUID SYSTEM INCLUDING EXTERNAL RESERVOIR, THREE 5-MICRON FILTERS, FILL PUMP, PRESSURE PUMP AND MANIFOLD OUTLETS FOR PRESSURE, SUCTION PULSE FLUSH AND WORK TANK BYPASS OUTLETS FOR PRESSURE, SUCTION, PULSE FLUSH AND WORK TANK BYPASS

8. WORK TANK FLUID LEVEL SAFETY SWITCH AND PLASTIC WORK TANK GUARDS WITH GAP POWER INTERLOCK SWITCH

9. MACHINE CONTROL STATION WITH CONTROLS FOR MACHINE ON/OFF, COOLANT ON/OFF, POWER ON-OFF, MANUAL SERVO WITH AUDIBLE EDGE-FINDER AND DITHER AUTO SERVO WITH SERVO SPEED, GAP ADJUST, RAM CYCLE AND ORBIT STOP/LOCK

10. H-PULSE MODEL 1004 100-AMP POWER SUPPLY INCLUDING:

EFFICIENCY METER WHICH ENABLES OPTIMUM CUTTING ADJUSTMENTS FOR GAP SPACING, SERVO SPEED OFF –TIME FLUSHING

INDEPENDENT ON –TIME, OFF-TIME AND PEAK CURRENT CONTROLS

AUTOMATIC, DUAL-SCALE AMMETER

PERCENT ON –TIME METER

CONVENIENT POLARITY SWITCH

ELECTRODE SWITCH FOR GRAPHITE OR METALLIC MATERIALS

NO WEAR CAPABILITY WITH GRAPHITE AND COPPER ELECTRODES

GAP INITIATION CONTROL PERMITS GAP VOLTAGE SELECTIONS OF 75, 150 AND 300 VOLTS

GAP MONITOR FAULT PROTECTION CIRCUITS PROVIDE AUTOMATIC SHUTDOWN IN THE EVENT OF OVER AMPERAGE, OVER VOLTAGE, IMPROPER GAP (DC ARCING) OR RESTRICTED AIRFLOW. FRONT PANEL RESET IS PROVIDED

EASY TO CHANGE, FURNACE TYPE AIR FILTER

ONE GAP CABLE FOR ONE TO TWO LEAD OPERATION